Make it solid

PROTOTYPING

SERVICES

From idea to form: quickly and reliably

We offer high-quality rapid prototyping services to help designers, startups, and companies bring their ideas to life with speed, precision, and confidence.

We provide direct access to a wide range of advanced technologies, carefully selected for their reliability and performance, and managed entirely from Europe.

Why work with US?

A single European contact – from file upload to final delivery

Fast and responsive – quotes within 24–48 hours

DDP shipping – we handle customs, taxes, and logistics

Flexible volumes – from one unit to small batches

Transparent pricing in euro – no surprises, no hidden fees

WHAT WE OFFER

Whether you need to test a form, validate a function, or impress stakeholders with a high-fidelity model, we’ll help you choose the best solution for your design and timeline.

CNC Machining

-

Ideal for high-precision functional parts, CNC machining allows us to produce prototypes in metal or plastic with tight tolerances and excellent surface finishes. It's especially suited for mechanical components, enclosures, or when you need fully functional parts that simulate the final product.

We offer 3-axis and 5-axis CNC milling and turning, with a wide range of materials including aluminum, stainless steel, brass, ABS, PC, POM, and more.

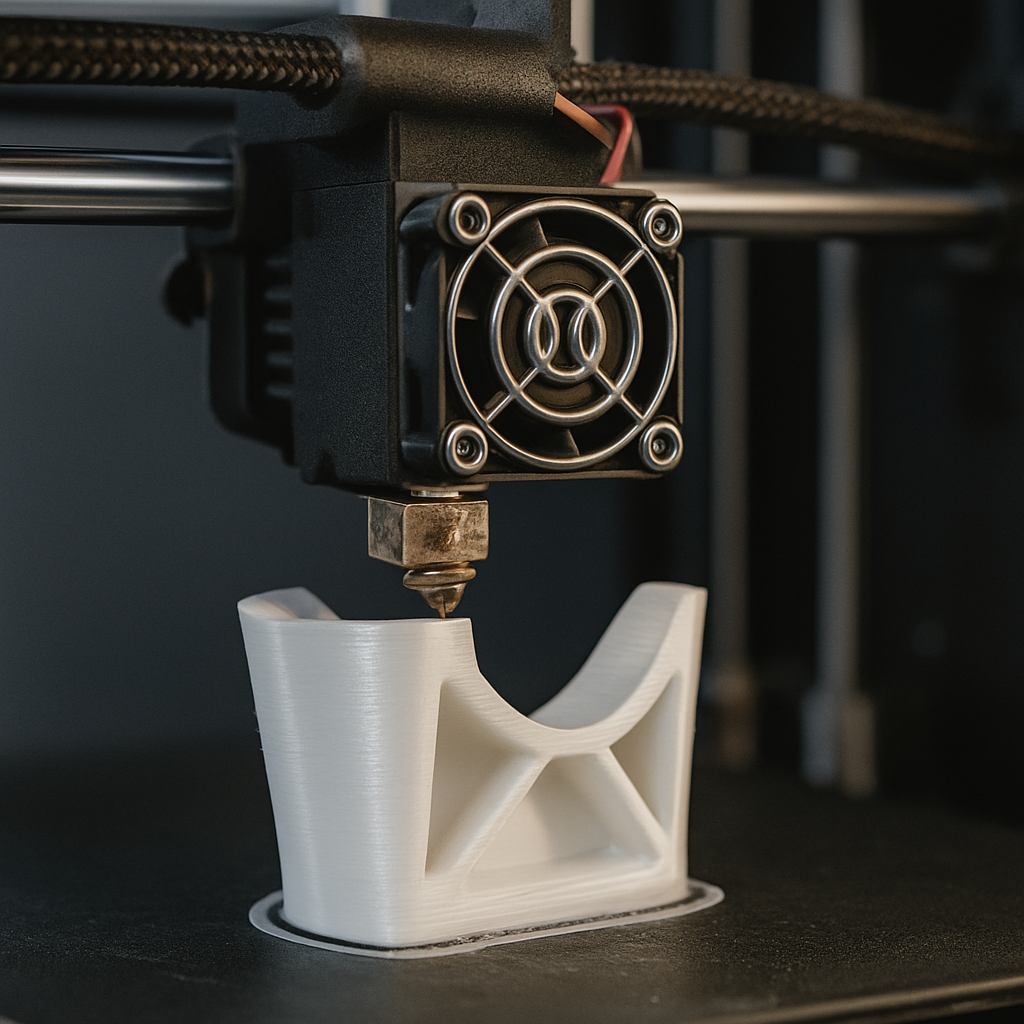

3D Printing

-

3D printing is the fastest and most flexible method to turn your digital model into a physical object. We support multiple technologies to meet different needs:

SLA: smooth, high-detail resin parts ideal for visual models

SLS: strong, functional nylon parts without support marks

MJF: excellent dimensional accuracy and consistency for small series

FDM: affordable and quick for early-stage prototyping

Perfect for concept models, ergonomic tests, or short-run iterative designs.

Sheet Metal Prototyping

-

When your design involves thin-walled metal parts, enclosures, brackets, or mechanical assemblies, sheet metal fabrication is the way to go.

We use laser cutting, bending, stamping, and welding to deliver precise and fast parts in materials such as aluminum, stainless steel, and galvanized steel.

Surface finishes include powder coating, anodizing, brushing, or plating, depending on your needs.

Vacuum Casting

-

Vacuum casting uses silicone molds to replicate parts in urethane resins that simulate the look, feel, and mechanical properties of injection-molded plastics.

It’s ideal when you need a small series of parts (5–50 units) with high visual quality and functional performance, such as design validation, marketing samples, or pre-series testing.

Available finishes include transparent, tinted, rubber-like, and overmolding simulations.

Carbon Fiber Prototyping

-

For projects requiring lightweight strength, carbon fiber prototyping offers outstanding performance.

We can deliver both real carbon fiber laminates and reinforced composite solutions for parts subject to stress or aesthetic demands.

This process is well suited for sport equipment, automotive components, drone parts, and high-end consumer products.

Start your

prototype today

Send us your 3D file and we’ll take care of the rest.

Not sure which process is best for you? We’ll advise you step by step.

Your ideas, made real – faster than you think.

Frequently asked questions

-

Prototypes are manufactured in collaboration with leading global providers of rapid prototyping and low-volume manufacturing. SECCI Concept Design is your sole point of contact for the entire process.

-

Yes. SECCI Concept Design handles all client communications from Europe, including:

Quotation and technical advice

Invoicing in euros

Shipping and customs

Customer service and warranty

-

For first-time orders, we ask for a 50% deposit at order confirmation and 50% before shipping.

Custom payment terms (e.g., Net 30) can be negotiated for repeat clients. -

If you're not satisfied with the delivered part, simply notify us within 7 days of delivery. We will arrange a free replacement or rework, pending technical review.

-

We follow ISO 2768-1 standards:

Machined metal: F

Machined plastic: M

Vacuum casting: C

Tighter tolerances may be possible depending on geometry and material, and must be discussed during quotation.

-

Products are shipped directly to the client, but the process is fully managed by SECCI. We offer DDP (Delivered Duty Paid) service across Europe, meaning no customs clearance or additional payments for the client.

-

Description text goeManufacturing takes place in a modern 12,000+ sqm facility in Dongguan, China, with engineering and project management teams based in Shenzhen. SECCI manages your entire project from Europe.s here

-

Rapid prototyping: within 24 hours

Rapid tooling: within 24 hours

Injection molding & production tooling: 2–3 days

Additional time may be needed for special materials or processes, which we will notify in advance.

-

Bank transfer in euros to SECCI Concept Design

PayPal, with a 4% service charge

-

DFM analysis (Design for Manufacturing) before production

Incoming materials inspection

Final QC check with full inspection report before shipping

-

Preferred formats:

.step or .iges + 2D drawing with key dimensions for CNC and molding

.stl or .obj for 3D printing

2D drawings alone can be quoted but may require more time.

-

Our manufacturing partners hold:

ISO 9001:2015

ISO 14001:2015

IATF 16949:2016