Why We Still Verify Moulds in Person

Reflections from the field on a practice that remains essential

In the product development process, mould verification is a critical yet often underestimated phase. In a time where digital workflows dominate every stage of design, it might seem unnecessary to visit the tool shop in person. And yet, we still do it.

The 3D file is not the mould

CAD modeling can be extremely precise, but a mould is never a perfect reproduction of the file. Between engineering and construction, technical compensations and constructional choices come into play—related to machinability, mechanical integrity, or tool longevity.

By directly following the mould engineering phase, we can monitor how the project is interpreted, translated, and adapted. It is a delicate step where the designer’s vision becomes a complex and functional system made of inserts, shutoffs, parting lines, and injection channels.

Visiting the factory: understanding to design better

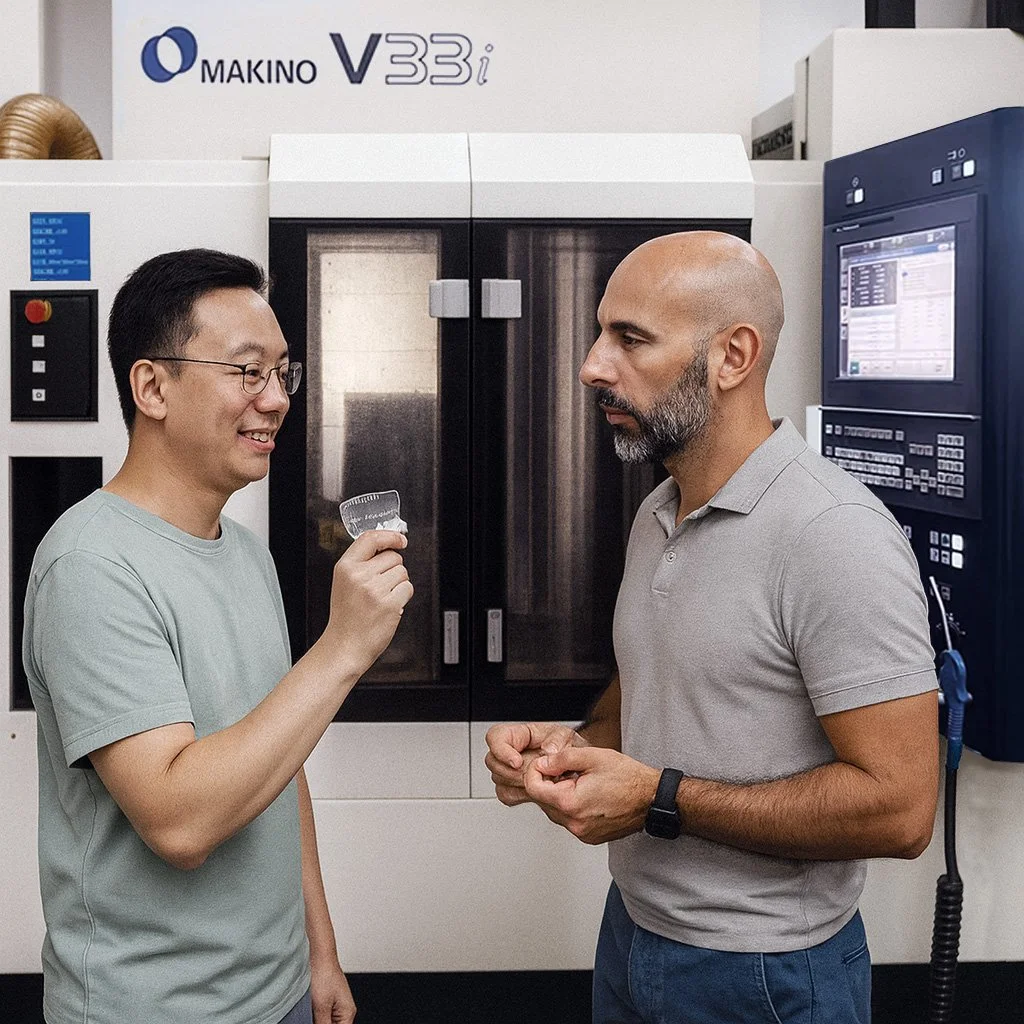

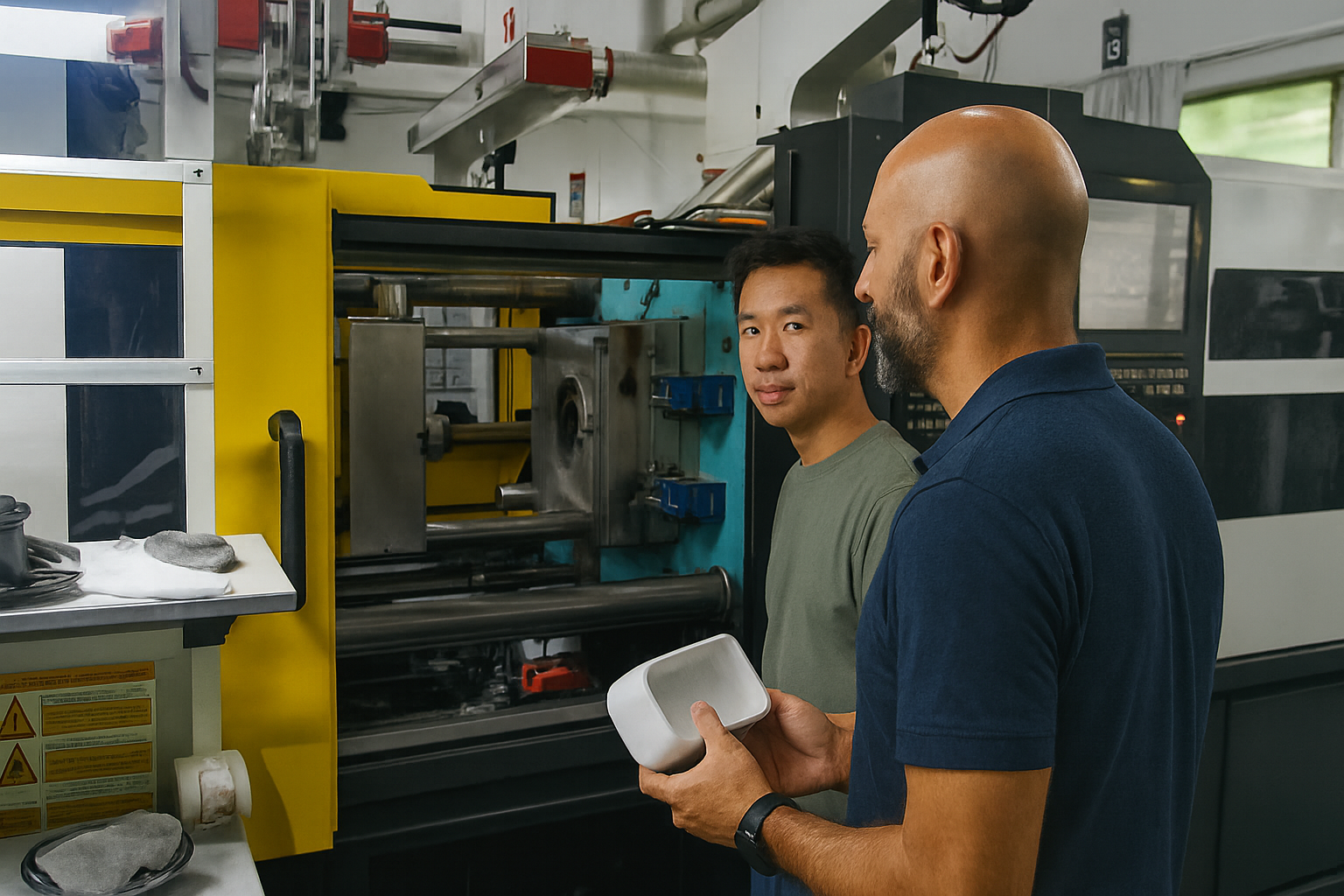

Being physically present in the tool shop, inspecting the moulds before closing, feeling the structure, discussing with mould makers—this allows us to understand why a product will be moulded in a specific way.

Why flash may occur, why a wall is slightly off-dimension, why a texture is uneven.

It’s hands-on learning. For designers working with physical products, these visits are invaluable educational moments. After experiencing injection moulding firsthand, every future design is approached with deeper awareness: in tolerances, geometries, textures, and parting lines. That awareness translates into faster timelines, reduced costs, and higher final quality.

Presence can’t be replaced

Photos and videos may document progress, but they don’t replace face-to-face evaluation. Only in person can you properly assess:

• texture depth and distribution

• selective polishing

• actual gate positioning

• undercut controls

• shutoffs and visual interferences

Verification is part of the project

Mould verification is not just a formal check. It’s an integral part of development, often the moment where design truly meets engineering. Direct feedback leads to more conscious choices and stronger integration between aesthetics, function, and industrial feasibility.